|

|

|

|

|

|

|

|

|

|

|

|

|

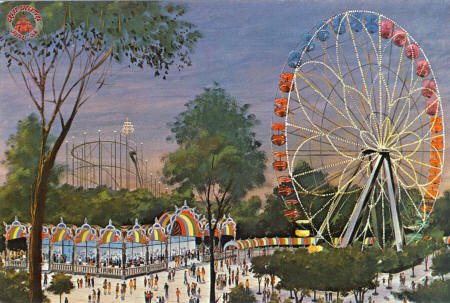

Designed to be what in the park industry

is known as a "weenie", the Giant Wheel was the larger than life draw at

the far end of Dream Street, bringing guests from the entrance plaza

into the heart of the Enchanted Forest.

The Giant Wheel was

purchased after having served as the centerpiece of the Holland Tulip

Festival, and at the time it was the World's Largest Ferris Wheel. The

ride promised to offer spectacular views from above the tree tops over

the entire park.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The strategy of the Enchanted Forest was to preserve as much of the

heavily forested property as possible, so the bare minimum number of

trees were removed around the future site for the ride. The parts all

arrived from Europe and assembly began. The first pieces installed were

the two massive footers which were designed for portability but had to

keep the wheel stable with ballast in the steel frames. The two footers

were held at the proper distance for the ride's assembly with a steel

frame between them to keep them at the proper distance apart as well as

to insure they remained parallel to one another during assembly. Once

the footers were in place the legs were assembled on the ground and

raised into position with a crane. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

With the first leg installed and held in place

with a cable, the second leg was raised with the crane and the two were

joined at the center of the ride, creating one side of the "A" shape to support the

central hub.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The ride was equipped with built in service steps

and railings allowing workers to climb the structure safely. The steps

lead to a platform at the top for easy assembly and maintenance of the

Giant Wheel's hub. With the legs in place, everything was bolted

together and secured.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The second set of legs went together the same way,

and with the four legs in place the hub was hauled into the

center connecting the two sides. The massive hub carries all the weight

of the ride as well as creating the electrical connections for the rides

lighting. Definitely not a job for those with a fear of heights!

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Once the hub was in place the spokes and outer

ring were assembled piece by piece and the wheel advanced section by

section temporarily secured to the legs. The frame of the wheel is strong but

light weight. Without the weight of the cars, moving the structure was

relatively easy as assembly continued. When the wheel was a complete

circle in the tradition of construction an American Flag was placed at

the highest point to signal the project had topped out.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

With assembly of the structure complete the four

motors were installed on the legs, and the elaborate floral lighting

strips were attached to the spokes. All of the electrical wiring was now

being installed so the motors could move the wheel as the cabins were

being installed. The operator's booth was also put in place at the

base. One of the final things to be done was the placement of wood

planking around the foundation to disguise the steel boxes.

|

|

|

|

|

|

|

|

|

Update Coming Soon! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Original Spotlight: March 14, 2012; Updated September 10, 2023. GAH Reference #: SHOP-1974-007 |

|

|

|

|

|